Why Using Bone Models for Orthopaedic Training Is So Important

Orthopaedics is such a procedure-oriented discipline that its mastery requires repeated exposure to an established set of techniques, best practices, and psychomotor skills. Bone models for orthopaedic training can become central to this process, providing the best of both accurate real-world simulation and robust materials that are consistent across repeated uses.

Research has established the suitability—and in some aspects, superiority—of engineered bone models over cadaveric alternatives, leaving instructors with the potential to custom design resources to their exact pedagogical requirements.

With a continually evolving set of technologies improving the effectiveness of models with every generation, the entire field of orthopaedics can look forward to better translating non-clinical study to professional procedural success.

Decades of Evolution

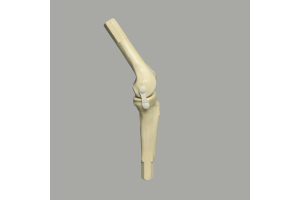

Synthetic bone models for orthopaedic training are an established suitable alternative to cadaveric specimens. This suitability reflects the evolution of bone models from rudimentary and largely visual approximations of bone dimensions to simulations with strength, compressive qualities, lateral bending stiffness, and cancellous properties that better represent living bone than cadaveric options.

It can be argued that once this level of replication was achieved, bone models became a far superior instrument for instruction than cadaveric specimens. This is because engineered models are generally cheaper, easier to store and maintain, offer advantages in scheduling and course design, and offer no disposal or ethical concerns. Furthermore, developed models can be designed to meet peak presentation standards across any bone, or joint, or network of bone connections.

The realism of synthetic bone models has equaled the established knowledge of the orthopaedic field to make instruction potentially more effective than ever before.

More than 2,000 Models and Materials

The leading producers of bone models for orthopaedic training stock thousands of unique designs. These models each authentically recreate the physical properties of individual bones and bone groups so that students can be guided through a near-exhaustive list of procedures and techniques. Without detailing every available resource, there are models that can effectively build competencies in the following core skills and procedures:

- Total joint replacement

- Internal fixation

- Intramedullary rodding

- External fixation

- Cortical screw application

- Complex imaging

The leading bone models are in fact accurate enough to be used in the testing, comparison, and development of implants and other devices. This is due to the development of advanced materials and technologies that lend the models both the necessary authenticity and an immersive, interactive element that promotes diagnostic, psychomotor, and non-surgical skills.

These features include:

- Composite bone materials that faithfully recreate the strength, bend, and cancellous resistance of human anatomy

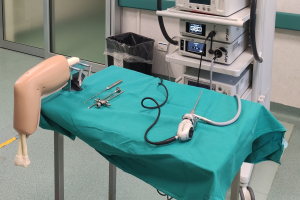

- Dual usage models offer the choice of open and closed interventions, allowing trainees to develop surgical skills and refine the psychomotor skills involved in advanced arthroscopic tools

- Foam cortical shell that provides the necessary stability and performance to accommodate the cutting and drilling of core procedures

- Transparent cortical shells that allow visualisation of internal procedures, such as screw fixation, among novice cohorts

- Radiopaque materials that enable medical imaging, with the option of including skin, muscle, and tissue

These models and materials are all designed with the intention of giving students a hands-on introduction to the physical aspects of various orthopaedic disciplines.

Drilling, Cutting, and Manipulating

While general orthopaedic training requires extensive knowledge of all the body’s joints and bones, the physical properties and advanced technologies of the latest bone models take students beyond core anatomy.

The materials and performance of the most advanced models give students a transferable experience of the forces required to conduct common procedures. Arthroscope developments have reduced the invasiveness of many procedures, but the use of screws, plates, and braces is still essential. These processes require the development of psychomotor skills dependent on hands-on instruction.

To meet this end, the latest benchtop models include a range of resources that can withstand repeated drilling or the application of bands and screws. There are dozens of models associated with fractures alone, covering the complete range of presentations from minor to severe. Drilling is among the most commonly used skills is daily orthopaedic practice, but there is a wide range of options currently in use. Studies into the effectiveness of the differing techniques have relied upon engineered models due to the superior reliability and performance of designed models over cadaveric specimens, especially those subject to long-term freezing.

The flexibility of purpose of these modern models, and their proven effectiveness in giving students a hands-on introduction to the complete diversity of orthopaedic disciplines, helps reduce the steep learning curve associated with such procedure-heavy fields.

Importantly, the development of even more specified models is limited only by the needs and learnings of teaching professionals.

Designer Bone Models for Orthopaedic Training

While there are thousands of bone models for orthopaedic training currently available, the effectiveness of modern design means there’s no need for instructors to limit their ambitions to existing options. Alongside the right engineering team, any professional can create a model that authentically and accurately recreates conditions, presentations, and procedures across any discipline.

The technologies discussed above represent only what has been done to date. Next generation resources can create unique mixes of materials and technologies to further decrease the learning curve associated with the hands-on nature of orthopaedics. These models can be produced to suit a single cohort or to be scaled for commercial sale across the world.

Model technology has reached a point where even a highly defined, procedure-driven field such as orthopaedics can be serviced with a complete range of reach and educational tools.

The orthopaedic training models created by Sawbones are designed with the mix of technology and durability necessary to facilitate the drilling, cutting, and hands-on manipulation needed for effective training. For more information on our offerings or to talk about custom training models, contact us online or at 206-463-5551.

If you're seeking something you can't find on our website, our sales team is happy to help. We can either direct you to the right model or provide a free quote on the right custom project to meet your needs. Discover options with our clear bone models, laminated blocks, custom displays, or other machining projects.