How To Balance the Cost of Bone Models with Their Long Term Value

"Price is what you pay; value is what you get," said Warren Buffet once, knowing that upfront costs sometimes belie the true value of an object. In orthopaedic and surgical training, the cost of bone models is recovered several times over by their versatility, consistency, and durability in the lab and medical classroom. Here are the considerations to make when evaluating costs.

Bone Models Advantages

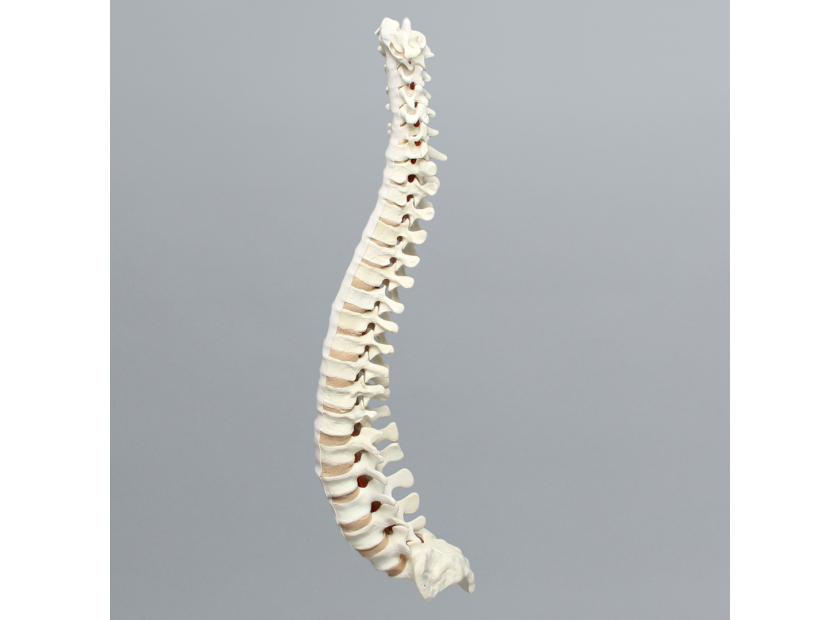

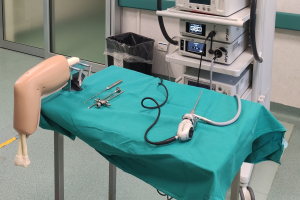

Bone models have long been preferred in orthopaedic research and biomechanical studies thanks to their advantages over organic specimens. Cadaveric specimens require special handling and have a limited shelf life. They also inordinately represent elderly patients compared to other segments of the population. On the other hand, artificial bone models offer greater consistency as well as realistic experience of a biological specimen when subjected to medical procedures. High-quality models mimic natural bone when tapped, cut, or drilled with surgical instruments.

Bone models are ideal for large-scale medical and surgical training as they are built to last and withstand repeated use. Likewise, their general availability and uniform structure cater to a learning environment which emphasizes mastery through training.

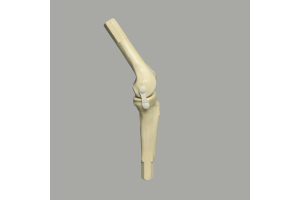

High-quality bone models are also adaptable to multiple training courses. For example, foam cortical shell models can be used to practice total joint replacements as well as internal fixation. The same model can be used to study fractures and pathology in common bone diseases such as osteoporosis and bone tumors. In the same way, a radiopaque model is useful for the practice of medical imaging and diagnoses as well as fixation and rodding techniques. Thus, bone models’ versatility adds to its long term value by serving different orthopaedic training scenarios.

Cost of Bone Models Against Long Term Value

High-quality materials, in spite of their higher upfront cost, present advantages over more economic options. Certain bone model types are also made for specific purposes while others are designed for broader use. See the table below to compare the cost of bone models with their common uses and advantages. For the purpose of comparison, a selection of roughly similar femur bone models is provided with their varying costs.

Bone Model Types |

Material |

Common Uses |

Advantages |

Sample Femur Model |

|

Composite Bone |

Solid fiberglass epoxy with no cancellous inner material |

•Testing/designing bone implants |

• Inexpensive compared with organic models used in load and motion testing • Uniform and consistent; less variable than cadaveric specimen • Mimics the feel and strength of natural bone |

Femur, 4th Gen., 15 PCF Cellular Foam Cancellous, Medium |

|

Solid Foam |

Rigid foam |

• Patient education and demonstration |

• Economical for use in general anatomy |

Femur, 15 mm Canal, Solid Foam, Left, Medium |

|

Foam Cortical Shell |

Rigid foam with inner cancellous component |

• Practice of total joint replacement procedures |

• Designed for cutting and drilling |

$17.25 |

|

Plastic Cortical Shell |

Rigid plastic shell with inner cancellous component |

• Training in internal fixation |

• Very durable |

Femur with 15.5mm Canal, Plastic Cortical Shell, Medium |

|

Solid Clear Plastic |

Solid clear plastic |

• General or patient education |

• Very durable |

Femur, Solid Clear Plastic, Left |

|

Solid White Plastic |

Rigid plastic |

• General or patient education |

• Very durable |

Femur, Solid White Plastic, Left |

|

Transparent Plastic Cortical |

Clear plastic shell and inner cancellous component |

• Rodding procedures where visibility of locking screws is required |

• End-to-end model visibility for specific procedures |

Femur, Transparent with 15.5mm Canal, Left |

|

Radiopaque |

Solid foam model with enriched visualization properties |

• Practice of medical imaging |

• Designed for medical imaging |

Femur, Radiopaque, Right, Medium |

It must be noted that 3D-printed bone models still face challenges such as high printing temperatures, cost of material (i.e. filaments), and biomechanical performance. As such, 3D-printed bone models are highly useful for preoperative planning in individual cases but not yet for the mass market. However, the technology is expected to advance and become a viable option in the future.

As seen in the table above, stronger materials such as fiberglass epoxy produce the best results for accurate testing and research scenarios. Lighter materials like foam are great for practical demonstration and training of basic procedures while sturdier materials like plastic work well with advanced procedures. Plastic models also double as product displays thanks to their superior durability. Investing in enhanced model types such as transparent/clear plastic models improves the quality of instruction and demonstration of internal fixation procedures. In all cases, higher quality pays out in terms of accurate results and greater durability in orthopaedic training and research.

Investing in Quality and Long Term Value

Ultimately, the upfront cost of bone models are far exceeded by their solid performance, long service, and wide versatility. Investing in high-quality bone models ensures higher standards of hands-on learning and instruction from the start. High-quality material also lasts longer and serves multiple uses in different training courses. Bone models’ long history of reliability in orthopaedic and surgical training has left their legacy unchallenged in the present and most likely in years to come.

Sawbones offers best-in-class bone models for orthopaedic training and biomechanical research. Our decades-long expertise balances the cost of bone models with long term value for repeatable performance. For more information on our offerings or to talk about custom training models, contact us at 206-463-5551.

If you're seeking something you can't find on our website, our sales team is happy to help. We can either direct you to the right model or provide a free quote on the right custom project to meet your needs. Discover options with our clear bone models, laminated blocks, custom displays, or other machining projects.