Flexible Encapsulated Joint Models Are Ideal Because of Their Versatility

Adding hands-on realism to medical training exercises is challenging. While the benefits of realism in models have shown promise in contributing to improved operating room performance, the technology involved in building interactive training models has been slow to take hold. The slow pace has been particularly noticeable when looking at the typical flexible joint models seen in clinical teaching settings.

Using a flexible encapsulated joint model will add an extra layer of model functionality and introduce higher realism to clinical training exercises. Emerging model manufacturing technologies have enhanced the realism required to translate classroom skills into progressive operating room successes, advancing pedagogy and clinical expertise.

How Realistic Can Flexible Encapsulated Joint Models Behave?

Referring to realism in medical training will often draw skepticism, but new encapsulated joint designs and model production methods have presented clinical and medical trainers with better options. The advances in new and higher levels of realism can be broken down into two particular points:

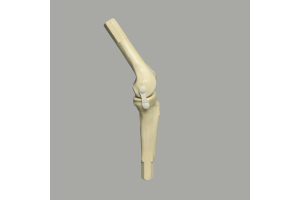

- Proper kinetic movement is a challenge as many models fail to incorporate the realism needed to recreate the joint's purpose. Encapsulated joint models may not include small details like the synovial fluid created by the synovial membrane that provides vital protection for joints. Or, they may fail to display accurate joint capsules, ligaments, and tendons both in form and function. Digital models can serve as an early solution and allow for consistent reuse. However, this just supports demonstration only training and is not in-depth enough for surgical practice exercises.

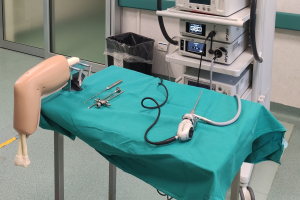

- New production methods have greater precision. A high-performance medical training model manufacturer will have blended materials to mimic the modeled encapsulated joints’ texture and strength qualities. Unique details like the outer fibrous layer of the joint capsule, or the cartilage included on the articular surfaces will be necessary for learning a wide range of common procedures. Higher-level features support training on everything from cortisone injections to keyhole surgeries like capsule release..

Versatility and Durability is a Key Factor When Selecting Teaching Models

As much as instructors lecture caution and diligence in any medical procedure, sometimes students make errors. With traditional models, errors often lead to the untimely destruction of the model. This loss is especially true with traditional encapsulated joint models, where the slightest wrong movement can damage small but critical features like bursae or menisci..

The most innovative medical model manufacturers have evolved designs and production workflows. Strong and highly flexible materials, digitized versions of models, and reusable models have elevated encapsulated joint models’ durability. Latex bandings have been improved for better tendon simulation, while the reinforced encapsulations protect and limit every joint’s flex.

These new training models allow instructors to remove the capsule for beginning students and then add them later as their skills advance. This option enables joint models to advance alongside students, streamlining the training process. The gradual scaling up of durability will improve each model’s overall versatility and cost-effectiveness.

Why Choose a Flexible Encapsulated Joint Model Over a Basic Model?

There are two primary reasons to switch from traditional joint models to encapsulated joint models: durability and realism. Basic models are initially less expensive, but the lack of durability will require replacement far more often than their flexible encapsulated joint model counterparts.

The overall usability and long-lasting nature of encapsulated joint models spread the higher costs over a more extended period. Comparatively speaking, this makes the lifetime costs of both model types somewhat similar. A flexible model works as a closer simulation of real joints, improving training and clinical success when the student enters the operating room.

The Benefits of Advanced Model Production Technology

Lifelike models refine the skills of those participating in medical training simulations. These advances provide students with a realistic simulation of joint anatomies, from ankles and knees and up to hips and elbows. When lifelike models are used in medical training, the result is more confident physicians. From both an economical and practical standpoint, encapsulated joint models demonstrate the highest value for future practitioners and patients.

Medical model manufacturers like Sawbones have spent the past four decades improving medical models in conjunction with notable medical programs and physicians. Our skilled team will work with you to design the highest quality clinical or educational models. To learn more about our services, please visit our contact page or call (206) 463-5551.

If you're seeking something you can't find on our website, our sales team is happy to help. We can either direct you to the right model or provide a free quote on the right custom project to meet your needs. Discover options with our clear bone models, laminated blocks, custom displays, or other machining projects.